The Power of Hemp in 3D-Printing

3D-printing has been growing in popularity in recent years due to its efficiency and customization capabilities. However, the use of traditional materials such as plastic has raised concerns about its impact on the environment. This is where hemp comes in, as it offers a sustainable and eco-friendly alternative.

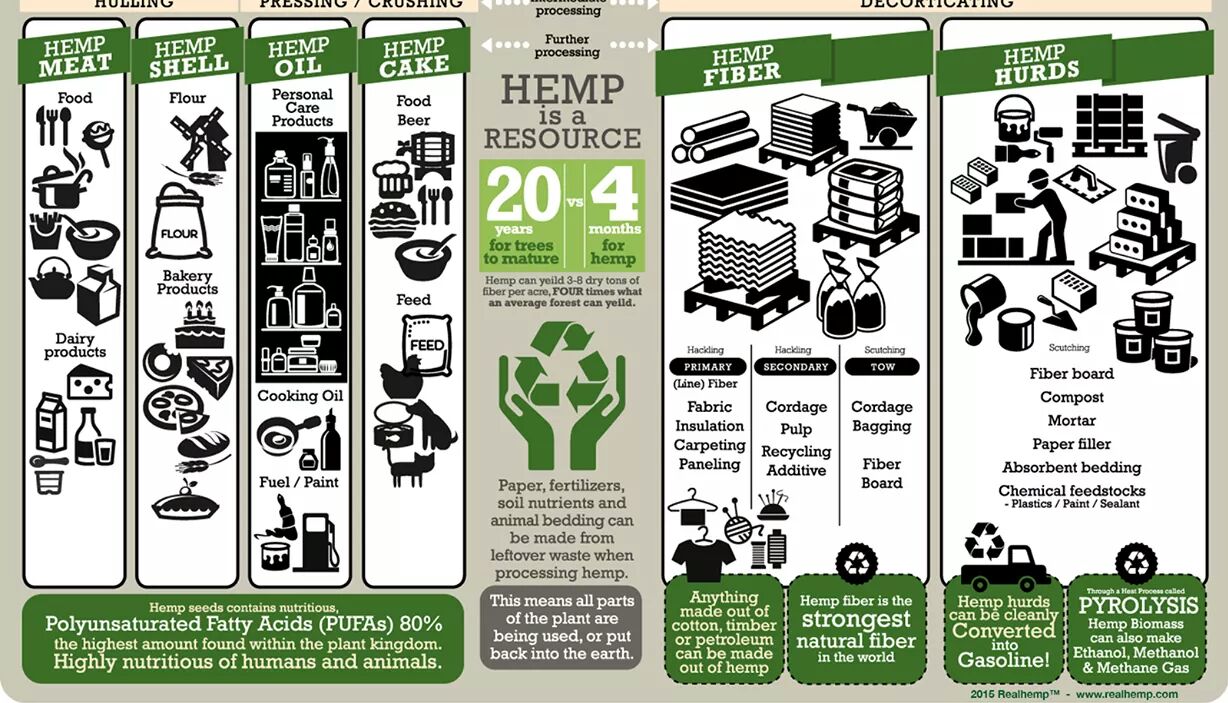

Hemp is a versatile crop that has been used for centuries in various fields, including textiles and medicine. Its strong fiber makes it an ideal material for 3D-printing, and its cultivation requires less water and pesticides compared to other crops.

In this article, we will explore the different techniques for harnessing the power of hemp in 3D-printing, its advantages, challenges, and future possibilities.

Hemp as a Sustainable Alternative to Traditional Materials

Plastic is a major component in traditional 3D-printing, and its production involves the use of fossil fuels and emits harmful gases. Hemp, on the other hand, is a renewable resource that requires less energy and water to produce. It also absorbs more carbon dioxide than other crops and can help reduce greenhouse gas emissions.

In addition, hemp can be grown without the use of pesticides and herbicides, making it a safer and healthier alternative for both the environment and workers.

Different Hemp-Based 3D-Printing Techniques

There are several techniques for using hemp in 3D-printing. One of the most popular is Fused Deposition Modeling (FDM), where hemp fibers are mixed with a thermoplastic material and then extruded through a nozzle to create a 3D object.

Another technique is Stereolithography (SLA), which involves using a laser to solidify a liquid resin that contains hemp particles. This method is more precise and can produce higher resolution prints.

The Advantages of Hemp-Fiber Materials

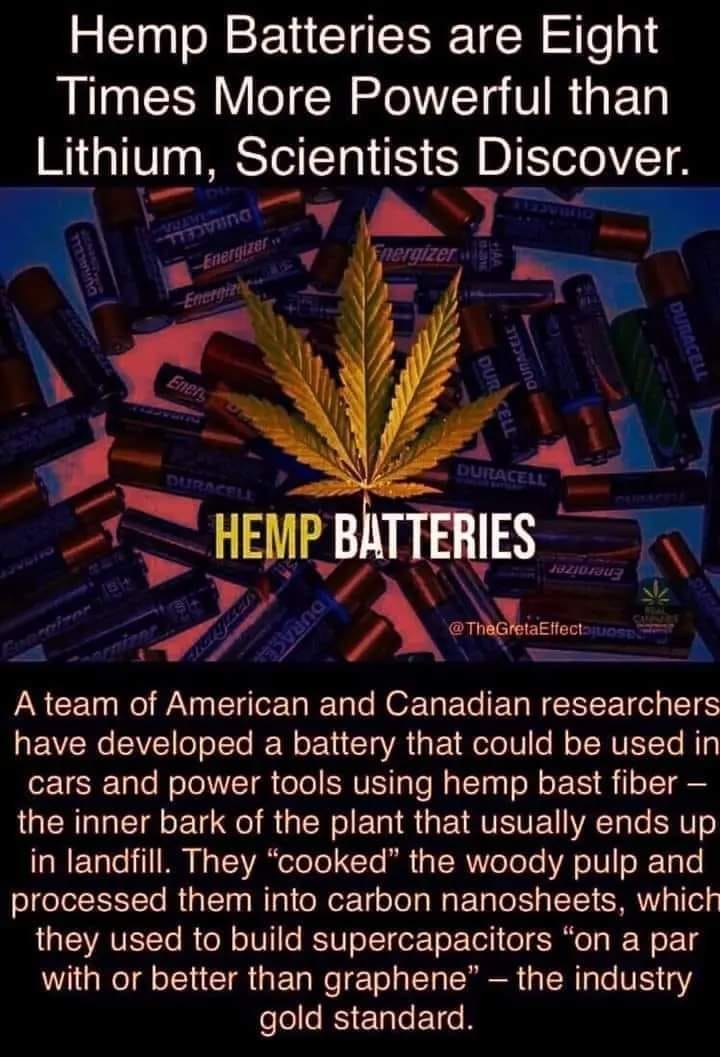

Hemp fibers offer several advantages over traditional materials. They are stronger and more durable, making them ideal for creating functional objects like tool handles, bike parts, and even car panels. Hemp fibers are also lightweight and biodegradable, making them a more sustainable option.

In addition, hemp fibers can be infused with other materials such as natural resins or recycled plastics to create composite materials that are even stronger and more versatile.

The Challenges of Using Hemp in 3D-Printing

One of the challenges of using hemp in 3D-printing is the availability of high-quality hemp fibers. Hemp fibers come in different grades, and only the highest quality fibers can be used for 3D-printing. This means that careful sourcing and processing are required to ensure the fibers are suitable for printing.

Another challenge is that hemp fibers can clog the printer nozzle or cause uneven extrusion. This can be overcome by using hemp particles that are smaller in size or by modifying the printer settings.

A Step-by-Step Guide to Printing with Hemp

To start 3D-printing with hemp fibers, you will need a 3D printer, hemp fibers, and a thermoplastic material such as PLA. Here are the steps:

- Mix the hemp fibers with PLA in a ratio of 1:5.

- Load the mixture into the printer nozzle.

- Adjust the printer settings to suit the mixture.

- Begin printing.

The Future of 3D Printing with Hemp

As the demand for sustainable and eco-friendly materials continues to grow, the use of hemp in 3D-printing is set to increase. Researchers are exploring new ways to improve the quality and availability of hemp fibers, and new techniques are being developed to create even stronger and more functional hemp-based materials.

Hemp and the Quest for Sustainable Manufacturing

Sustainable manufacturing involves reducing waste, minimizing pollution, and conserving resources. The use of hemp in 3D-printing is a step towards achieving this goal. By using a renewable resource that requires less energy and water to produce, we can reduce our impact on the environment and create a more sustainable future.

Hemp-Based 3D-Printing and Circular Economy

Hemp-based 3D-printing can also contribute to the circular economy by reducing waste and promoting a closed-loop system. Hemp fibers can be recycled and reused to create new materials, reducing the need for virgin materials and minimizing waste.

Hemp and the Ecological Benefits of 3D Printing

The ecological benefits of 3D-printing with hemp include reduced carbon emissions, lower water use, and less pollution. By using a renewable resource that absorbs more carbon dioxide than other crops, we can reduce our impact on the environment and create a more sustainable future.

The Role of Hemp in Reducing Carbon Footprint

The use of hemp in 3D-printing can help reduce our carbon footprint by lowering our reliance on fossil fuels and promoting sustainable manufacturing. Hemp absorbs more carbon dioxide than other crops, making it a valuable tool in the fight against climate change.

Hemp-Based 3D Printing for a Greener Future

Hemp-based 3D-printing offers a sustainable and eco-friendly alternative to traditional materials. By harnessing the power of hemp, we can create functional and durable objects while reducing our impact on the environment. With continued research and development, hemp-based 3D-printing has the potential to revolutionize manufacturing and create a greener future.