Plastic pollution has become a global crisis, with devastating effects on ecosystems and human health. The production and disposal of conventional plastic pose significant environmental challenges, including carbon emissions, water pollution, and land degradation. While recycling and biodegradable materials are gaining traction, a more sustainable and scalable solution is needed. Hemp, a versatile plant with various industrial applications, offers a promising alternative to plastic. In this article, we explore the technical roadmap of replacing plastic with hemp-based bioplastics.

The Advantages of Hemp as a Replacement Material

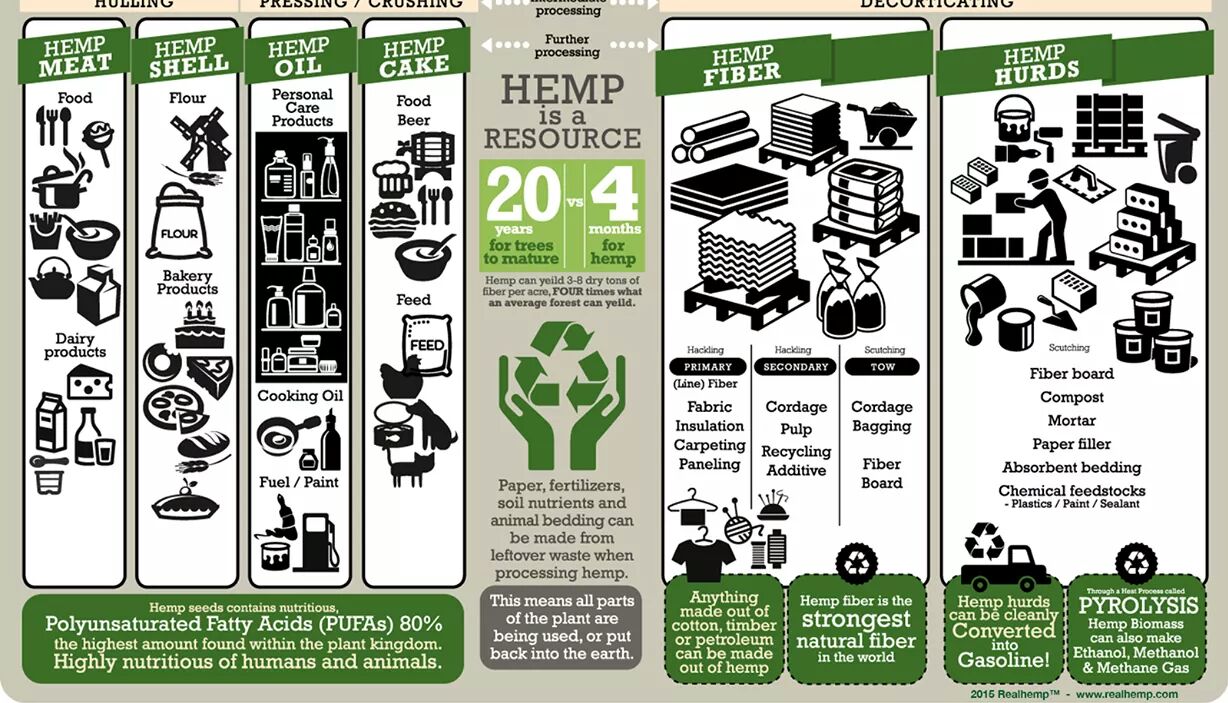

Hemp is a fast-growing crop that requires minimal water and pesticides, making it a highly sustainable crop. It has a high yield per acre, producing up to four times more paper than trees. Hemp can be grown in diverse regions worldwide, reducing the need for transportation and minimizing carbon emissions. Additionally, hemp is a renewable resource that can be used for various applications, including textiles, construction, and bioplastics.

Technical Properties of Hemp for Manufacturing

Hemp fibers are strong, durable, and lightweight, making them ideal for manufacturing. They have excellent tensile strength, meaning they can handle stress without breaking. Hemp fibers are also antimicrobial, resistant to UV light, and can be processed into various forms, including yarn, rope, and paper. The cellulose component in hemp fiber can also be used to produce bioplastics.

Hemp-Based Bioplastics: A Sustainable Solution

Hemp-based bioplastics are an eco-friendly alternative to petroleum-based plastics. They are made from renewable resources and can be biodegradable, reducing the amount of plastic waste in landfills and oceans. Hemp bioplastics have the potential to replace a wide range of plastic products, including packaging, utensils, and automotive parts.

Industrial Applications of Hemp-Based Bioplastics

Hemp-based bioplastics have a wide range of industrial applications. They can be used in the production of lightweight car parts, reducing emissions and improving fuel efficiency. Hemp bioplastics can also replace traditional plastic bags and packaging, reducing waste and toxicity. Additionally, hemp bioplastics can be used in medical devices, reducing the risk of infections and improving patient outcomes.

Processing Hemp for Bioplastic Production

Hemp fibers can be processed in various ways to produce bioplastics, including mechanical pulping, chemical pulping, and enzymatic pulping. The choice of processing method depends on the desired properties and end-use of the bioplastic. The process involves separating the cellulose fibers from the hemp plant, which are then modified and combined with other biodegradable materials to form the final product.

Formulation of Hemp-Based Bioplastics

The formulation of hemp-based bioplastics involves mixing the cellulose fibers with other biodegradable materials such as starch, corn, and soybean protein. The choice of materials and proportions depends on the desired properties and end-use of the bioplastic. The resulting mixture is then processed and shaped into the desired product, such as utensils, packaging, or car parts.

Mechanical and Thermal Characterization of Hemp Bioplastics

The mechanical and thermal properties of hemp bioplastics are essential for determining the suitability of the material for various applications. The mechanical properties include strength, stiffness, and toughness, while thermal properties include melting temperature, heat resistance, and thermal expansion. Testing these properties helps to optimize the formulation and processing of hemp bioplastics.

Biodegradability and Environmental Impact of Hemp Bioplastics

The biodegradability of hemp bioplastics depends on the formulation and processing of the material. Biodegradability testing involves exposing the material to various environmental conditions, such as soil, compost, and seawater, and monitoring its decomposition. Hemp bioplastics have a low environmental impact compared to traditional plastics, reducing carbon emissions, waste, and toxicity.

Challenges and Limitations of Hemp-Based Bioplastics

Despite its potential, hemp-based bioplastics face several challenges and limitations. One of the main challenges is the lack of infrastructure for large-scale production and processing. Another challenge is the high cost of production due to limited supply and processing capabilities. Additionally, the variability of hemp fibers and the lack of standardized testing methods can affect the quality and consistency of the bioplastic.

Scaling Up Hemp-Based Bioplastics Production

To scale up hemp-based bioplastics production, several strategies can be employed. These include investing in research and development to optimize the formulation and processing of the material, developing standardized testing methods, and improving infrastructure for large-scale production and processing. Additionally, policies and regulations can be implemented to promote the use of hemp-based bioplastics and reduce the use of traditional plastics.

===

Replacing plastic with hemp-based bioplastics offers a sustainable and scalable solution to the global plastic crisis. Hemp’s unique properties make it an ideal replacement material for various industrial applications, including bioplastics. While challenges and limitations exist, investing in research and development and improving infrastructure can help to overcome these obstacles. The future of sustainable materials lies in innovative solutions such as hemp-based bioplastics.