Hemp, a member of the Cannabis sativa plant family, has been used for thousands of years for various purposes. However, it is only recently that the potential of using hemp in the construction industry has started to gain attention. Hemp has unique properties that make it an ideal building material, and its use can help to create sustainable, non-toxic buildings. Innovations in hemp-based construction are opening up new possibilities for builders, architects, and designers to create greener, healthier, and more durable buildings.

Benefits of Hemp as a Building Material

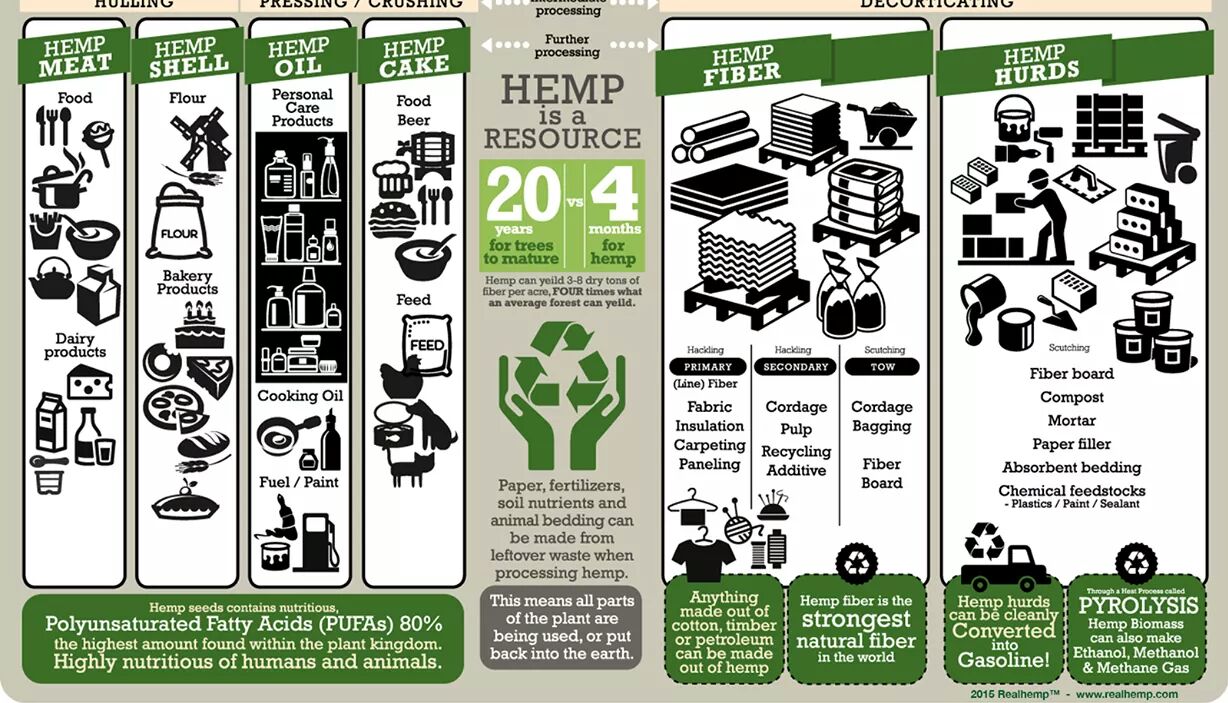

Hemp has several benefits that make it a desirable building material. It is a renewable resource that can be grown quickly and abundantly, requiring minimal water and pesticides. Hemp also has a low carbon footprint, as it absorbs more CO2 than it emits during its growth cycle. Additionally, hemp is a durable material that resists pests, mold, and fire. It is also lightweight and easy to work with, making it a convenient option for construction projects.

Hempcrete: Properties and Applications

Hempcrete is a mixture of hemp hurds (the woody core of the hemp plant) and lime. Hempcrete is an ideal building material due to its insulating properties, fire resistance, and breathability. It is also non-toxic and produces no off-gassing, making it an excellent option for those who are sensitive to chemicals. Hempcrete is commonly used for insulation and wall systems, and it is also suitable for flooring and roofing.

Challenges in Hemp-Based Construction

Hemp-based construction is still a relatively new field, and there are some challenges to overcome. Hemp materials are not yet widely available, and there is a lack of research on the long-term performance and durability of hemp-based products. Additionally, hemp regulations can vary from state to state, and there is a lack of standardization in the industry.

Innovations in Hemp-Based Insulation

Innovations in hemp-based insulation are making it more accessible and affordable for builders. Hemp-based insulation is made from compressed hemp fibers, which have excellent insulating properties. It is also breathable and moisture-resistant, helping to prevent mold growth. New manufacturing techniques are also improving the consistency and quality of hemp insulation products.

Hemp Fibers: Improving Structural Integrity

Hemp can also be used to enhance the structural integrity of buildings. Hemp fibers can be integrated into building materials such as concrete or plaster, improving their tensile strength and reducing their overall weight. This can result in stronger, more durable structures that are less prone to cracking or damage.

Hemp-Based Composites: Strength and Durability

Hemp-based composites are a new and exciting development in the construction industry. These composites are made from a combination of hemp fibers and resins, creating a material with superior strength, durability, and flexibility. Hemp composites can be used for a variety of applications, including flooring, roofing, and exterior cladding.

Designing Sustainable Buildings with Hemp

Hemp-based construction is an excellent way to create sustainable buildings that are healthier for occupants and the environment. By using hemp, builders can reduce the carbon footprint of their projects, create non-toxic and energy-efficient buildings, and promote sustainable agriculture practices.

Regulatory Barriers and Solutions

Regulatory barriers can pose a challenge to the widespread adoption of hemp-based construction. Regulations can vary from state to state, and some building codes may not yet recognize hemp as a viable building material. However, there are solutions to these challenges. Builders can work with local policymakers to create more favorable regulations and codes, and promote the benefits of hemp-based construction to the public.

The Future of Hemp-Based Construction

The future of hemp-based construction is bright. As more research is conducted, and innovations in hemp-based materials continue to emerge, hemp will become a more widely accepted and accessible building material. Hemp-based construction can help to create a more sustainable, non-toxic, and healthy built environment for future generations.

Case Studies: Successful Hemp-Based Projects

Several successful hemp-based construction projects have already been completed around the world. These projects include the House of Hemp in the Netherlands, a hempcrete house in California, and a hemp-based office building in Germany. These projects demonstrate the viability and potential of hemp-based construction, and they serve as examples for future builders and designers.

Why Hemp is the Future of Construction

Hemp is a versatile and sustainable building material that has the potential to revolutionize the construction industry. Through innovations in hemp-based materials, builders can create healthier, more durable, and more energy-efficient buildings. While there are still challenges to overcome, the future of hemp-based construction is bright, and it is exciting to see what new possibilities will emerge in the coming years.